Avoid Doing the Wrong things Righter…But, “By What Method?”

Deming Institute

JUNE 30, 2020

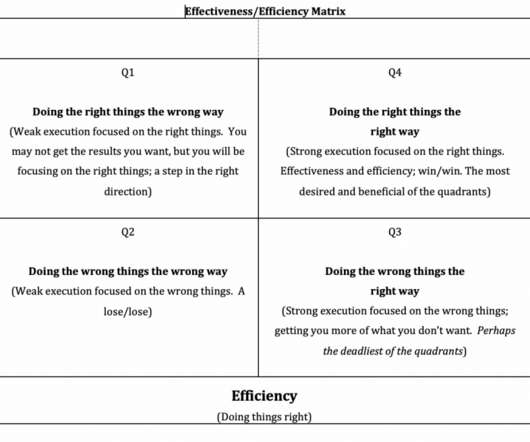

Learning to do things “right” is important and all sorts of training exist for doing so, including Lean Six Sigma, Kaizen, Plan-Do-Study-Act, Statistical Process Control, and ISO certifications to name just a few. To that end, Dr. Deming might well ask, “By what method” can we determine the “right” things to do? Mark Lane, 2019).

Let's personalize your content