How AI Fits into Lean Six Sigma

Harvard Business Review

NOVEMBER 9, 2023

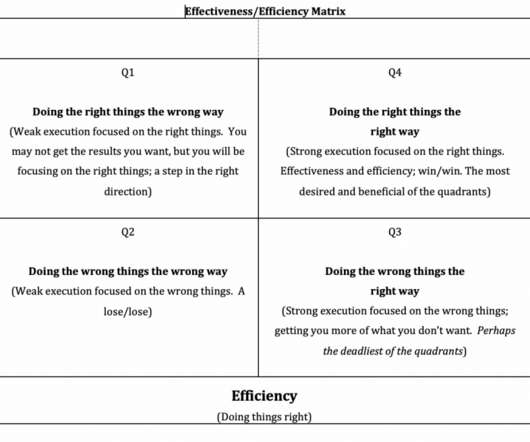

AI already is being used in some areas of process improvement, and the usage of this technology — including generative AI — promises to grow. That’s because it can perform tasks faster and much less expensively than humans alone. But it will never fully replace people — and that poses management challenges.

Let's personalize your content